Unlock the Ultimate Performance of Heat Tools Through Mastery of Key Elements

What Core Components Make Up Effective Heat Tools?

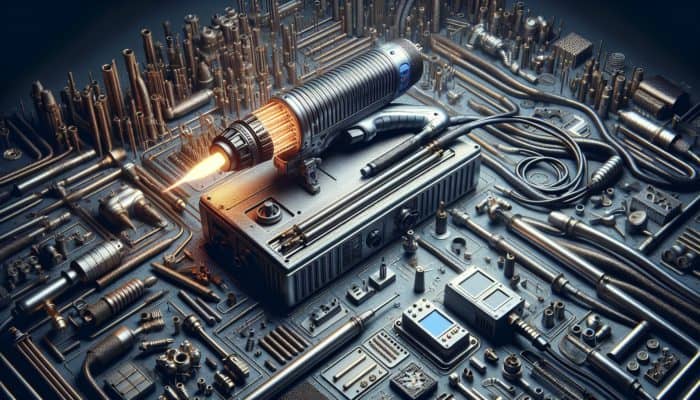

Understanding the core components of heat tools is essential for maximising their performance while simultaneously mitigating the risks associated with improper use. These tools consist of crucial elements, including heating elements that generate the required heat, temperature controls that allow for precise adjustments, and Nozzles that direct the heat flow effectively. Additionally, power sources energise the tools, while features like insulation, sturdy housing for durability, safety systems to protect the user, and ergonomic design significantly improve functionality and user experience. A comprehensive grasp of these components enables users to ensure efficient operation in various applications.

- Heating Element

- Temperature Control

- Nozzles

- Power Source

- Insulation

- Housing

- Safety Features

- Ergonomic Design

What Fundamental Guidelines Ensure Safe and Effective Use of Heat Tools?

To ensure both safety and effectiveness when using heat tools, it is critical to adhere to fundamental guidelines that significantly improve operational performance. Key practices include acquiring a thorough understanding of the tool's functions, wearing suitable personal protective equipment, maintaining a tidy and organised workspace, and confirming that tools are properly calibrated before each use. By familiarising themselves with the operational functionalities of each tool, users can maximise efficiency and considerably enhance safety during various tasks.

Moreover, consistently following the manufacturer's instructions is vital for achieving the best results while ensuring user safety. By adhering to these best practices, users can significantly reduce the chances of accidents and improve overall tool performance, ultimately creating a safer and more productive working environment.

How Do Heat Tools Improve Operational Processes Across Industries?

Heat tools are crucial to a wide range of operational processes in various industries, facilitating tasks such as welding, soldering, and heating materials. Their ability to deliver precise heat is essential for maintaining operational consistency and minimising errors. This precision ensures that tasks are completed efficiently, leading to reductions in waste and optimised outcomes.

In sectors where accuracy is vital, such as electronics and construction, the significance of heat tools is immense. Their functionality streamlines workflows, enhances productivity, and maintains quality standards, highlighting their indispensable role in achieving operational excellence.

What Role Does Optimisation Play in Boosting Operational Efficiency?

What Effective Methods Can Be Used to Evaluate Tool Performance?

Assessing the performance of heat tools is crucial for identifying inefficiencies and enhancing overall productivity. Common evaluation techniques encompass monitoring temperature consistency, assessing output quality, and conducting time-efficiency analyses. By employing universal metrics such as energy consumption rates and turnaround times, users can pinpoint areas requiring improvement and make informed adjustments to their practices.

These assessment methods, when consistently adopted, ensure that tools operate at peak performance, resulting in superior results across various applications. Regular performance evaluations promote a culture of continuous improvement, fostering excellence in tool management.

What Factors Are Critical for the Success of Optimisation Initiatives?

Several key variables significantly influence the success of optimising heat tools. These factors include the quality of materials used, the level of user expertise, and the specific conditions under which tools operate. Effectively adapting strategies to address these variables is essential for ensuring consistent effectiveness across diverse working environments.

For example, utilising high-quality heating elements can greatly enhance performance and longevity, while ensuring comprehensive training for operators improves their ability to effectively use tools. This synergy between quality and skill fosters more efficient workflows, maximising both productivity and safety.

What Advantages Are Gained from Regular Maintenance Routines?

Implementing regular maintenance routines for heat tools yields numerous advantages, including enhanced longevity, reliability, and optimal performance. Routine inspections facilitate the timely identification and rectification of any signs of wear and tear, thereby preventing potential failures during crucial tasks. These proactive maintenance practices are vital for sustaining operational efficiency and ensuring user safety.

Furthermore, regular maintenance helps prevent the accumulation of dirt and debris that can impair the efficiency and performance of tools. By highlighting the importance of maintenance, users can prolong the lifespan of their heat tools and ensure they function at peak capacity, thereby improving the overall effectiveness of their work environment.

Acquire Expert Knowledge for Optimising Heat Tools

What Advanced Techniques Can Be Employed for Precise Control?

To achieve precise control when using heat tools, users should embrace advanced techniques that enhance their applications. This involves meticulously adjusting temperature settings and employing nozzles specifically designed for particular tasks, ensuring the correct tool is utilised for each job. For instance, using a lower temperature for delicate materials while increasing settings for tougher materials can prevent damage and yield better results.

Real-world applications demonstrate the effectiveness of these methods. In the electronics field, for example, soldering requires exact temperature control to avoid damaging sensitive components, underscoring the need for expert knowledge in optimising heat tools. By mastering these techniques, users can achieve high-quality outcomes while minimising the risk of errors, highlighting the importance of skill in tool management.

How Can Tools Be Integrated into Existing Workflows Smoothly?

To seamlessly integrate heat tools into existing workflows, meticulous planning and execution are essential for maximising productivity. Users should focus on creating an environment where tools complement one another, thereby enhancing overall output. This may involve using tools that share common energy sources or can be interchangeably used for specific tasks, streamlining operations and minimising downtime.

Moreover, ensuring that all team members are trained to use the tools effectively promotes smooth operations and maximises efficiency across projects. A well-coordinated team that understands how to leverage each tool to its fullest potential can greatly enhance productivity and project success.

What Common Pitfalls Should Be Avoided During Optimisation Efforts?

Successfully navigating heat tool optimisation requires avoiding common pitfalls that could hinder progress. Issues such as neglecting regular maintenance, disregarding safety precautions, and failing to properly calibrate tools can significantly diminish efficiency and introduce safety hazards. Recognising these potential challenges empowers users to take proactive measures to mitigate risks effectively.

Establishing a maintenance schedule and keeping detailed records of tool performance can help prevent these errors. By addressing potential issues before they escalate, organisations can safeguard their operations and ensure optimal tool efficiency, ultimately fostering a more productive and safe working environment.

What Recommendations Do Experts Provide for Maintenance and Longevity?

Experts strongly recommend adhering to best practices for the routine maintenance of heat tools to ensure consistent performance and prolonged lifespan. This includes establishing inspection schedules to identify signs of wear and tear, developing systematic cleaning protocols, and promptly replacing any worn components. Regular inspections help uncover minor issues before they escalate into major problems, while cleaning protocols prevent debris accumulation that may hinder performance.

Following these expert recommendations not only extends the lifespan of tools but also maximises operational efficiency. A proactive maintenance strategy ensures that heat tools remain reliable and effective, ultimately supporting the overall success of projects and operations.

How Can Innovative Approaches Enhance Energy Efficiency?

Enhancing energy efficiency in heat tools involves embracing innovative methods aligned with contemporary sustainability goals. Implementing smart controls that allow for precise temperature regulation, coupled with the use of eco-friendly materials in tool design, represent leading strategies within the industry. Such innovations contribute to reduced energy consumption while optimising output.

For instance, tools equipped with intelligent temperature sensors can autonomously adjust their settings according to the material being processed, ensuring energy is utilised effectively without compromising performance. This technological advancement not only fosters sustainability but also significantly enhances the overall efficiency of heat tool applications.

What Key Benefits Does Optimisation Offer Users?

How Does Optimisation Improve Safety Measures in the Workplace?

Optimisation greatly enhances safety by minimising hazards associated with the use of heat tools. By using well-maintained tools and ensuring users receive adequate training, the likelihood of accidents is substantially decreased. This focus on safety is particularly critical in high-stakes environments where heat tool usage is prevalent.

Moreover, optimised tools often incorporate advanced safety features, such as automatic shutoff mechanisms and improved insulation, which further enhance user safety when operating under challenging conditions. These features play an essential role in fostering a safer working environment, significantly reducing the risk of injuries or equipment damage.

What Role Does Optimisation Play in Enhancing Resource Efficiency?

Optimisation is key to improving resource efficiency, effectively reducing waste during operations. By streamlining processes and ensuring tools operate at peak efficiency, organisations can conserve valuable resources, contributing to broader sustainability efforts. This emphasis on efficiency is not only environmentally responsible but also yields economic advantages.

Key efficiency metrics reflecting the impact of optimisation include:

- Energy consumption rates

- Material waste reduction

- Tool lifespan extension

- Time efficiency in operations

- Cost savings

- Product quality improvement

These metrics enable businesses to evaluate the effectiveness of their optimisation strategies and make informed decisions for future enhancements, ensuring they remain competitive within their respective markets.

What Long-Term Advantages Do Users Gain from Optimisation?

The long-term benefits of optimisation for users are substantial, encompassing durability, reliability, and ease of use across various contexts. Optimised heat tools are specifically designed to withstand the demands of frequent use, ensuring they consistently meet performance standards over time. This focus on durability enhances user satisfaction and reduces the frequency of replacements.

In addition, optimised tools offer a superior user experience through improved ergonomics and more intuitive controls, making them easier to handle. This not only boosts productivity but also enhances user satisfaction, contributing to overall operational success and reinforcing the importance of investing in high-quality heat tools.

How Can Optimisation Lead to Financial Benefits and Cost Reductions?

Optimisation significantly reduces costs by refining processes and eliminating inefficiencies, ultimately enhancing profitability for businesses. This improvement leads to better financial management, allowing for reinvestment into growth areas and bolstering economic resilience across sectors. The financial advantages of optimisation are clear in decreased operational costs and increased revenue potential.

By focusing on optimising heat tools, organisations can realise significant cost savings, thereby enhancing their competitive edge in the marketplace. Effective budget allocation becomes achievable, as resources are freed up to support innovation and expansion, paving the way for sustainable future growth.

How Does Optimisation Foster Innovation and Adaptability?

Optimisation encourages innovation by integrating cutting-edge technologies and adaptive strategies that enable organisations to respond effectively to shifts in market demand. This cultivates a culture of continuous improvement, enhancing competitiveness and ensuring long-term success in dynamic environments. Companies that embrace innovation can stay ahead of industry trends and swiftly respond to evolving market requirements.

This adaptability is crucial for maintaining relevance and achieving sustained growth in challenging conditions. By prioritising optimisation, organisations position themselves for success, fostering a forward-thinking approach to their operations and ensuring they thrive within a competitive landscape.

Research-Backed Advantages of Optimising Heat Tools

What Evidence-Based Methods Can Help Reduce Damage?

Implementing evidence-based strategies for optimising heat tools is vital for minimising damage across various applications. Techniques such as maintaining appropriate temperatures and selecting the correct tool for each task ensure that materials are handled effectively. This careful methodology reduces risks associated with overheating or improper usage, directly correlating with improved outcomes and extended tool longevity.

Moreover, expert analysis indicates that adopting specific operational protocols can further enhance the effectiveness of heat tools, enabling users to achieve optimal results while minimising potential damage. These evidence-based strategies are essential for upholding high standards in tool performance and reliability.

How Does Optimisation Support Consistent Results?

Optimisation guarantees consistent results by controlling all variables that influence performance. Data-driven insights into reliability demonstrate that tools operating at optimal levels yield predictable outcomes, thereby reducing variability in results. This consistency is particularly crucial in industries where quality assurance is paramount.

Organisations that implement these optimisation strategies can expect improvements in product quality and service delivery, reinforcing their reputation as reliable players in their respective markets. Consistency in tool performance fosters customer trust and loyalty, ultimately leading to long-term business success.

How Can Research Findings Be Integrated into Daily Practices?

Incorporating research findings into daily practices is essential for achieving improved outcomes with heat tools. Users should focus on adopting techniques proven effective in various studies while also emphasising flexibility to adapt to different working environments. This approach ensures that the latest advancements inform operational practices, enhancing performance and safety.

For instance, conducting regular training sessions based on the latest research equips staff with the necessary knowledge to optimise tool usage, directly improving productivity and material safety. By fostering a culture of learning and adaptation, organisations can continuously refine their practices and outcomes.

Why Is Effective Damage Control Essential in Optimisation?

What Risks Are Associated with Poor Management of Heat Tools?

Inadequate management of heat tools can lead to significant risks, including heightened safety hazards, decreased efficiency, and material damage. When tools are not properly maintained or utilised, the likelihood of accidents increases, adversely affecting both personnel and equipment. This negligence can also result in costly downtime and repairs, negatively impacting overall productivity.

Moreover, failing to optimise tool usage can generate expensive errors that disrupt project timelines and budgets. Proactive management is crucial for effectively mitigating these risks, ensuring that tools operate safely and efficiently while delivering reliable results.

What Strategies Can Be Employed for Proactive Issue Prevention in Tool Management?

Proactive issue prevention strategies are essential for ensuring operational stability when using heat tools. This includes establishing regular inspection schedules, providing user safety training, and continually monitoring performance metrics. By prioritising these actions, organisations can identify potential problems before they escalate, ensuring that tools remain in optimal condition and function safely throughout their lifecycle.

Such strategies not only enhance safety but also contribute to operational efficiency, reducing the potential for unexpected disruptions. A proactive approach to tool management fosters a culture of responsibility and care among users, leading to improved performance and outcomes.

How Can the Effectiveness of Control Measures Be Measured?

Measuring the effectiveness of control measures is crucial for evaluating the success of optimising heat tools. This involves establishing clear success metrics, such as incident rates, equipment downtime, and user feedback. Regular reviews and adjustments based on these metrics guarantee that optimisation efforts deliver the desired results, promoting continuous improvement.

Implementing a broad applicability in monitoring efforts allows organisations to make adjustments that enhance their processes over time. By adopting a data-driven approach to tool management, organisations can ensure sustained improvements in both performance and safety.

Advanced Techniques for Maximising the Effectiveness of Heat Tools

What Innovations in Heat Tool Design Enhance Functionality?

Emerging innovations in heat tool design are transforming functionality within the industry, accommodating a wide range of applications. Contemporary designs often incorporate features such as ergonomic handles, adjustable temperature settings, and efficient heat distribution mechanisms, all aimed at enhancing user experience and performance. These advancements not only improve usability but also enhance safety, ensuring that tools meet modern user expectations.

Key design elements include:

- Ergonomic grips

- Temperature regulation systems

- Lightweight materials

- Modular attachments

- Smart technology integration

- Safety shutoff mechanisms

- Durable housing

- Improved insulation

These innovations not only enhance the usability of heat tools but also elevate safety standards during operation, reinforcing the critical importance of innovation in tool design.

How Can Tools Be Customised to Meet Specific Needs?

Customising heat tools to meet specific needs is crucial for enhancing versatility and functionality. Users can adapt tools by employing interchangeable attachments or adjusting temperature settings according to the materials being processed. This level of customisation boosts performance across diverse applications, enabling users to execute tasks more efficiently without compromising quality.

Tailoring tools to specific projects ensures optimal results, fostering greater user satisfaction. Such personalised approaches to tool usage not only enhance productivity but also contribute to the overall success of projects, underscoring the value of flexible tool management.

What Protocols Should Be Established for Optimised Performance Testing?

Establishing rigorous testing protocols is vital for ensuring optimised performance in heat tools. Standard verification processes should include assessments for temperature accuracy, consistency in heat application, and evaluation of user safety features. By implementing a structured testing approach, organisations can identify potential issues before they adversely affect operations.

Ongoing assessment and refinement of these protocols guarantee that tools remain reliable and efficient over time, supporting sustained operational excellence. This commitment to quality assurance is crucial for maintaining high standards in tool performance and user safety.

Best Practices for Continuous Control of Heat Tools

Why Are Routine Checks and Adjustments Essential?

Conducting routine checks and adjustments is vital for maintaining high standards in the operation of heat tools. Regular inspections should focus on evaluating tool performance, identifying signs of wear, and ensuring that all safety features function correctly. By prioritising these practices, organisations can prevent unexpected failures and maintain optimal operational efficiency.

Establishing a consistent maintenance schedule not only preserves the integrity of tools but also enhances overall operational safety. Regular attention to tool health ensures that users can rely on their equipment during critical tasks, ultimately contributing to successful project outcomes.

How Can Comprehensive Training Methods Be Implemented for Effective Use?

Implementing comprehensive training is crucial for promoting effective utilisation of heat tools. This includes offering hands-on workshops, providing detailed instructional materials, and facilitating ongoing education about the latest techniques and safety protocols. By ensuring access to training resources, organisations can guarantee that all users are well-prepared to operate tools efficiently and effectively.

Such training initiatives lead to optimised outcomes across various applications, reinforcing the critical importance of knowledge and skill in tool management. A well-trained workforce is essential for maximising the potential of heat tools, directly impacting productivity and safety.

What Factors Should Be Evaluated for Long-Term Tool Health and Optimal Performance?

Evaluating long-term tool health involves assessing indicators of durability and sustained performance. Users should concentrate on factors such as repair frequency, performance consistency, and user feedback regarding tool efficiency. Regular assessments help identify trends over time, allowing organisations to make informed decisions regarding tool replacements or upgrades.

This proactive approach ultimately supports sustained operational excellence, ensuring that heat tools remain effective and reliable throughout their lifecycle. By prioritising tool health, organisations can enhance overall productivity and safety.

FAQs

What Are the Primary Types of Heat Tools Available?

The primary types of heat tools include soldering irons, heat guns, hot air tools, and thermal adhesive applicators. Each serves distinct purposes, ranging from electronics soldering to crafting applications, showcasing the versatility of heat tools across various industries.

How Can I Extend the Lifespan of My Heat Tools?

To prolong the lifespan of heat tools, it is crucial to conduct regular maintenance, ensure proper storage, and adhere to manufacturer guidelines. Routine inspections and timely repairs are vital for preventing major breakdowns, thereby extending the usability and performance of the tools.

What Safety Precautions Should I Follow When Using Heat Tools?

Safety precautions include wearing protective gear, ensuring adequate ventilation, and familiarising oneself with the tool's functions. Always follow the manufacturer's safety guidelines to minimise risks associated with tool usage.

How Does Temperature Control Influence Heat Tool Performance?

Temperature control is critical for tool performance as it prevents overheating and ensures materials are processed effectively. Accurate temperature settings lead to enhanced outcomes and a reduced risk of damage to both materials and tools.

What Are Common Signs of Tool Wear That I Should Be Aware Of?

Common indicators of tool wear include inconsistent heating, unusual noises, visible component damage, and diminished performance. Monitoring these signs helps guarantee timely maintenance and extends the lifespan of the tool.

Can Heat Tools Be Used for Multiple Applications, and How Should I Adjust Them?

Yes, many heat tools are versatile and suitable for a variety of applications. However, it is crucial to adjust settings and utilise appropriate attachments for different tasks to achieve optimal results and ensure effective, safe use across diverse projects.

What Maintenance Routines Should I Consistently Implement?

Maintenance routines should encompass regular cleaning, component inspection, calibration of temperature settings, and replacement of worn parts. Establishing a maintenance schedule ensures consistent performance and longevity, maximising the effectiveness of heat tools in operations.

How Can I Reduce Energy Consumption While Using Heat Tools?

Reducing energy consumption can be achieved by optimising tool settings, using energy-efficient models, and implementing smart technology that adjusts power usage in response to real-time needs. Such practices contribute to cost savings and promote environmental sustainability.

What Are the Consequences of Neglecting Tool Maintenance?

Neglecting tool maintenance can lead to diminished efficiency, increased accident risks, and higher repair or replacement costs. Regular upkeep is essential for optimal performance, ensuring tools function reliably throughout their lifecycle.

How Do I Select the Appropriate Heat Tool for My Specific Project?

Selecting the right heat tool involves considering your project's specific requirements, including material type, desired temperature range, and task complexity. It is advisable to conduct research and compare models to ensure you choose the best tool for your needs.

Connect with us on Facebook!

The Article: Optimising Heat Tools for Damage Control: Essential Strategies appeared first on Amitys Hair Salon.

The Article Optimising Heat Tools: Key Strategies for Damage Control Was Found On https://limitsofstrategy.com

The Article Heat Tools Optimisation: Essential Strategies for Damage Control found first on https://electroquench.com